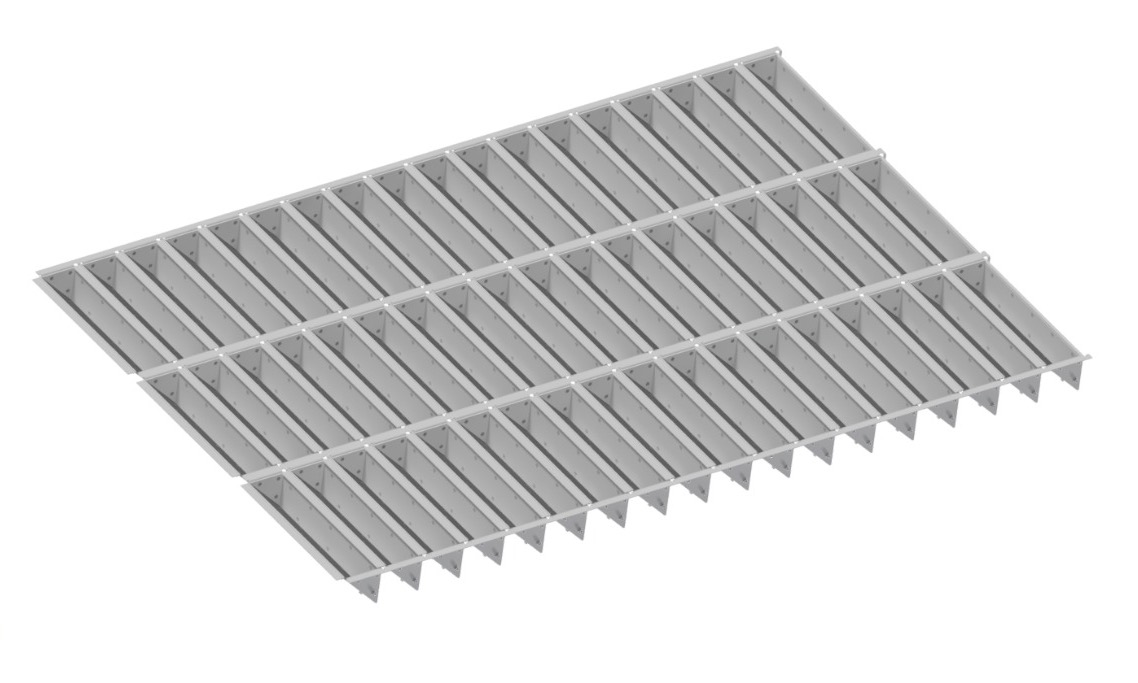

SKIF Flex-Flap

SKIF Flex-Flap is a dust suppression flap system designed to localize dust generation and improve aspiration efficiency at bulk material discharge and transfer points.

The solution limits dust dispersion, stabilizes airflow, and reduces uncontrolled air ingress into aspiration systems.

Flex-Flap can be used as a standalone dust suppression element or integrated into SKIF filtration and aspiration solutions, increasing overall system efficiency while reducing energy consumption.

Contact us

Key advantages:

- Pivoting flap elements create a controlled discharge zone and prevent dust from spreading into the working environment.

- Reduced uncontrolled air ingress allows the aspiration system to operate more stably with lower pressure losses.

- Optimized airflow reduces the required air volume and lowers the load on fans and filtration equipment.

- Curtain materials are resistant to abrasion and mechanical stress, suitable for continuous industrial operation.

- Simple installation on existing equipment without modification of the system design.

Without Flex-Flap

- Dust spreads beyond the discharge zone

- Uncontrolled ambient air ingress

- Unstable aspiration performance

- Higher required airflow rate

- Increased fan load

- Higher energy consumption

- Poorer working conditions and increased airborne dust

With SKIF Flex-Flap

- Dust localized directly at the discharge point

- Controlled airflow zone is formed

- Stable and predictable aspiration operation

- Lower required airflow rate

- Reduced fan load

- Optimized energy consumption

- Cleaner work area and improved occupational safety compliance

Payback calculator

SKIF Flex-Flap increases overall aspiration efficiency, reduces energy demand, and improves operating conditions — without complex equipment modifications.

Start with the customer – find out what they want and give it to them.