Flexibility and versatility

→ Packaging into bags up to 50 kg and big bags, suitable for different production scales and product types.

Engineering systems for accurate dosing, efficient packaging and stable continuous processes.

Packing systems are designed for controlled handling and accurate dosing of bulk materials at the final stage of the production process. They play a key role in ensuring stable operation, predictable logistics and consistent product quality.

Efficient packing directly affects throughput, labour requirements and operational reliability. Poorly designed packing solutions lead to product losses, weight deviations, increased downtime and unstable process performance.

In grain processing, feed production and other bulk material industries, packing is not an auxiliary operation but an integral technological function that completes the production cycle and prepares the product for storage and shipment.

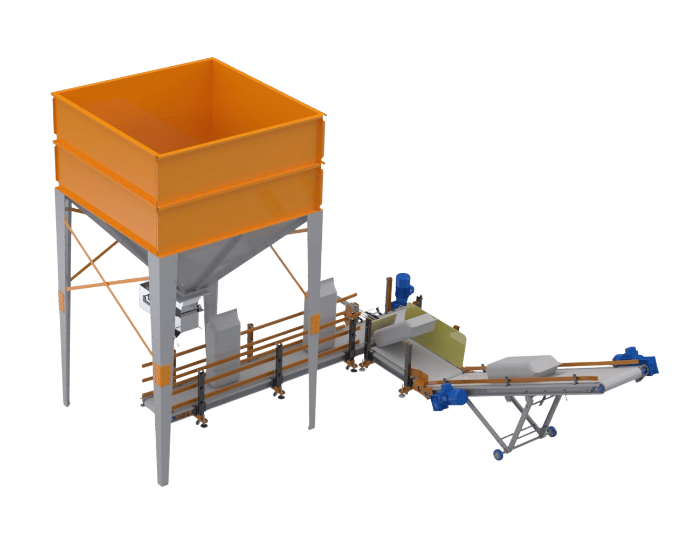

SKIF packing systems are engineered as modular solutions combining flexible product feeding, reliable dosing and seamless integration into existing production lines.

System architecture allows adaptation to different container types, loading concepts and operating modes, ensuring stable performance across varying production scales and product flows.

The product loading process can be organised using different feeding concepts depending on plant layout, throughput requirements and container type:

Standard option: loading using a front loader

Mechanised solutions: bucket elevators, screw conveyors, modular belt conveyors, chain conveyors

For rigid containers of fixed sizes: a tipper-lifter solution eliminates the need for additional storage hoppers and conveyors, reducing system footprint and overall investment costs

This flexibility allows seamless integration of the packing system into existing production lines.

SKIF applies a customized engineering approach to every packing project. Systems are designed based on product characteristics, throughput requirements, available space and operational conditions.

Before implementation, a detailed analysis of the production environment is carried out to ensure optimal system configuration. This approach allows SKIF to deliver reliable, scalable and efficient packing solutions suitable for both small facilities and large-scale industrial plants.

Start with the customer – find out what they want and give it to them.