One of the key processes in grain processing is the vertical movement of grain using bucket elevators. However, traditional bucket elevators have several drawbacks that reduce the efficiency of grain storage and processing plants.

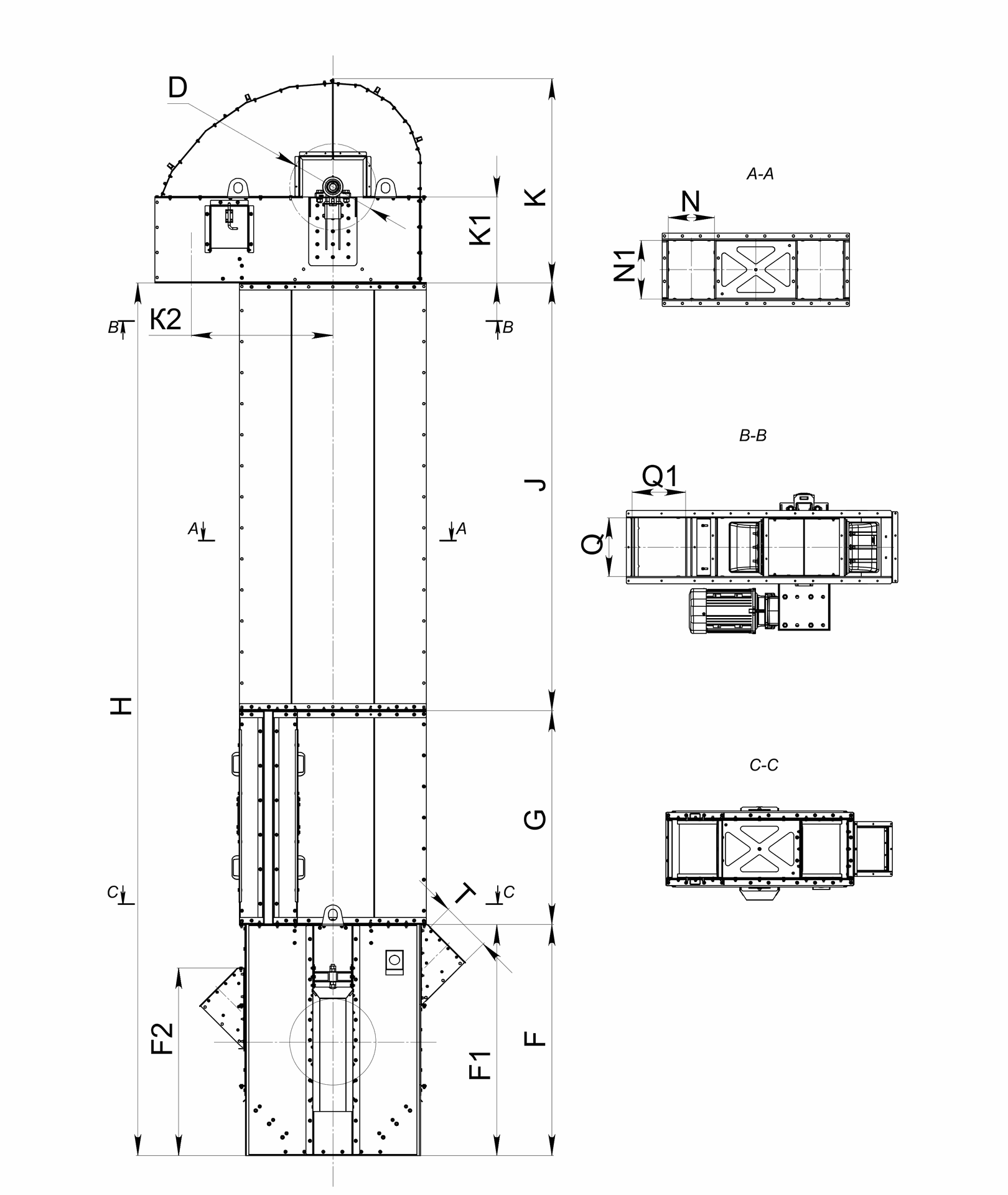

SKIF TECHNOLOGY GROUP specialists, together with leading STIF engineers, identified the main issues with existing bucket elevators and developed an improved design for the ECOTRU bucket elevators.

Key Problems and Innovative Solutions

The main drawbacks of traditional bucket elevators:

- Crushing of grain by the edges of the buckets.

- Insufficient reliability of the structures.

- High operational costs.

- Exceeding allowable concentrations of explosive dust.

Modern requirements for transportation equipment demand a balance between the quality of technological processes, grain preservation, energy efficiency, and safety. SKIF TECHNOLOGY GROUP specialists have developed a comprehensive solution that significantly improved the design of the ECOTRU bucket elevators.

Optimization of Elevator Operation

To minimize grain damage, studies were conducted to identify factors that cause destructive stresses, such as:

- Lack of synchronization between the grain flow speed and the driving element.

- Bucket and discharge device geometry.

- Reverse product spillage.

As a result, the following improvements have been implemented:

- A patented grain feeding system reduces damage by 1.5%.

- The use of flow stabilizers reduces destructive loads.

- STIF buckets with rounded edges reduce mechanical impact on the grain.

- The geometry of the upper part of the elevator and discharge hopper has been optimized to minimize kinetic energy losses.

Economic Efficiency and Reliability

Some manufacturers reduce the cost of equipment by decreasing the diameter of the drive drums, which leads to an increase in grain crushing. Studies have shown that when transporting grain using an elevator with a drum diameter of 530 mm, the damage coefficient increases by 1.5% compared to similar equipment with 720 mm diameter drums.

Reliability and Safety of the New Generation

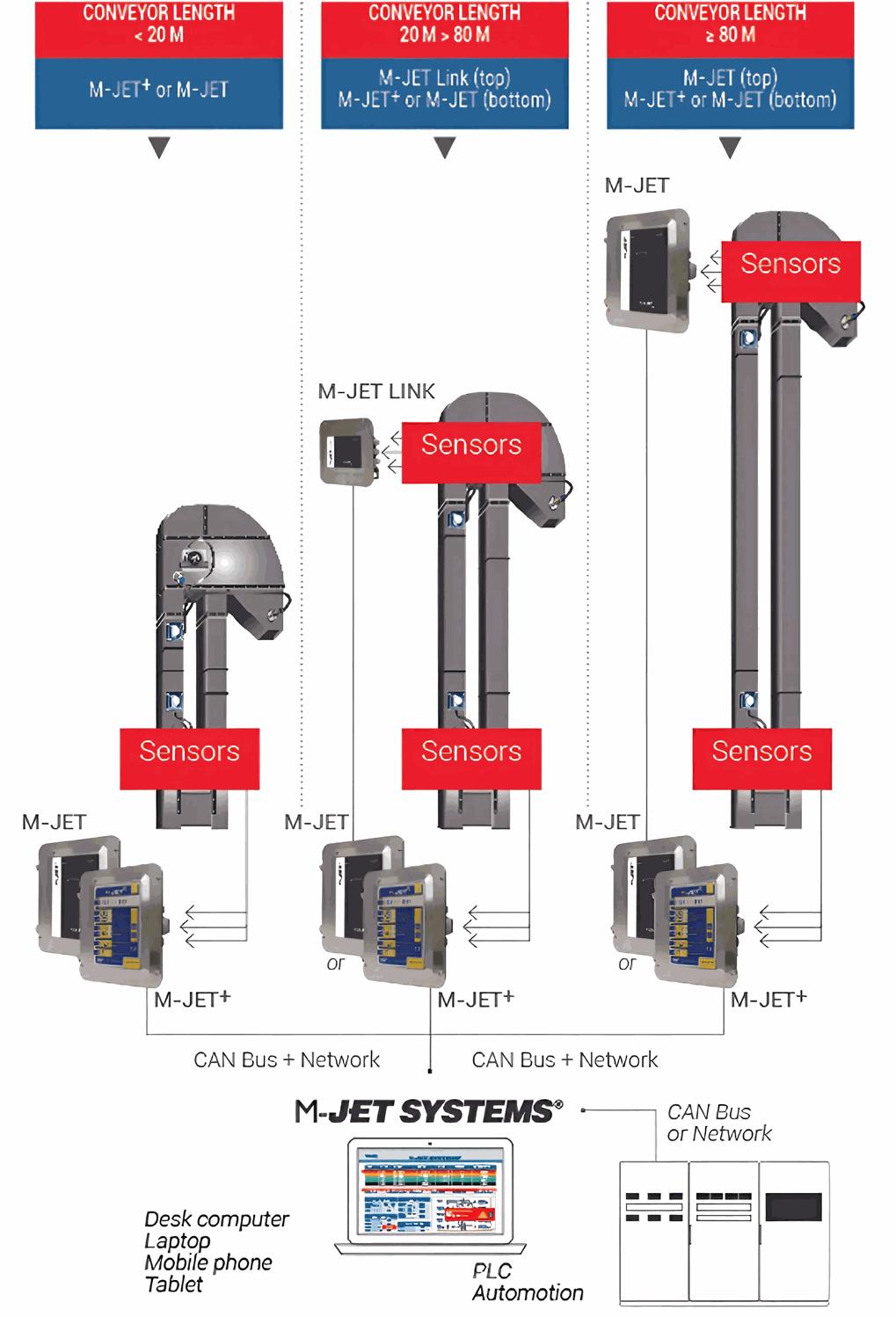

Moreover, ECOTRU bucket elevators are equipped with a self-diagnosis and operational parameter control system, which includes:

- Monitoring the technical condition of components.

- Managing transportation processes.

- Optimizing energy consumption.

- Automatic maintenance scheduling.

Thanks to the implementation of innovative solutions, ECOTRU bucket elevators ensure maximum energy efficiency, reliability, and safety. They significantly outperform existing analogs, offering customers an advanced technological system that meets the strictest requirements of modern grain processing.