Вертикальне транспортування зерна є одним із ключових процесів у зернопереробній галузі. Проте традиційні ковшові елеватори мають низку недоліків, що знижують ефективність зберігання та переробки зерна.

Фахівці SKIF TECHNOLOGY GROUP у співпраці з провідними інженерами STIF проаналізували основні проблеми існуючих ковшових елеваторів і розробили вдосконалену конструкцію – елеватори ECOTRU.

Ключові проблеми та інноваційні рішення

оловні недоліки традиційних ковшових елеваторів:

- Подрібнення зерна через гострі краї ковшів.

- Недостатня міцність конструкції.

- Високі експлуатаційні витрати.

- Перевищення допустимого рівня вибухонебезпечного пилу.

Сучасні вимоги до транспортувального обладнання потребують оптимального балансу між якістю технологічних процесів, збереженням зерна, енергоефективністю та безпекою. Фахівці SKIF TECHNOLOGY GROUP створили комплексне рішення, яке суттєво покращило конструкцію елеваторів ECOTRU.

Оптимізація роботи елеватора

Зменшення пошкоджень зерна, щоб мінімізувати пошкодження зерна, було проведено дослідження для виявлення основних чинників, що викликають руйнівні навантаження:

- Невідповідність швидкості руху зерна та елементів приводу.

- Недосконала геометрія ковшів і механізму вивантаження.

- Зворотне висипання продукту та повторний удар об ковші.

Впроваджені вдосконалення:

- Запатентована система подачі зерна, що знижує рівень пошкоджень на 1,5%.

- Стабілізатори потоку, які зменшують механічне навантаження.

- Ковші STIF із закругленими краями, що мінімізують механічний вплив на зерно.

- Оптимізована геометрія верхньої частини елеватора та приймального бункера, що зменшує втрати кінетичної енергії.

Економічна ефективність та надійність

Деякі виробники знижують собівартість обладнання, зменшуючи діаметр приводних барабанів, що, своєю чергою, призводить до збільшення рівня пошкоджень зерна. Дослідження показали, що при використанні елеватора з барабаном діаметром 530 мм коефіцієнт пошкодження збільшується на 1,5% порівняно з моделями, обладнаними барабанами 720 мм. Завдяки оптимізованій конструкції елеватори ECOTRU забезпечують високу надійність і мінімальні втрати зерна.

Нове покоління безпеки та надійностi

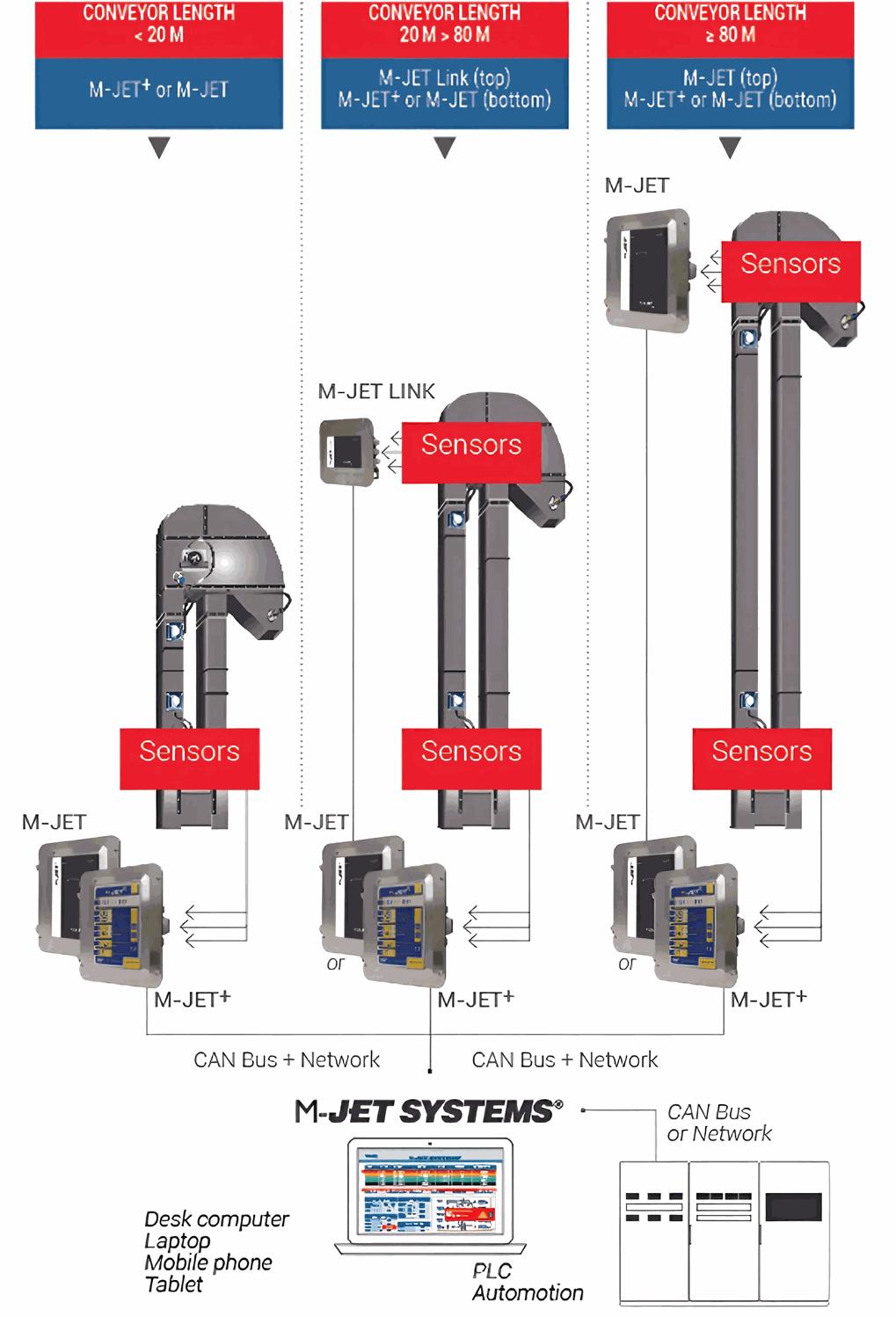

Елеватори ECOTRU оснащені сучасною системою самодіагностики та моніторингу робочих параметрів, що включає:

- Контроль технічного стану компонентів у режимі реального часу.

- Автоматизоване управління транспортним процесом.

- Оптимізацію енергоспоживання.

- Автоматичне планування технічного обслуговування.

Завдяки впровадженню інноваційних рішень, норії ЕКОТРУ забезпечують максимальну енергоефективність, надійність і безпеку.

Елеватори ECOTRU випереджають аналоги, пропонуючи інноваційну технологічну систему, яка відповідає найвищим стандартам зернопереробної галузі.

Обирайте елеватори ECOTRU – інвестуйте у безпечне та ефективне транспортування зерна!