M-JET

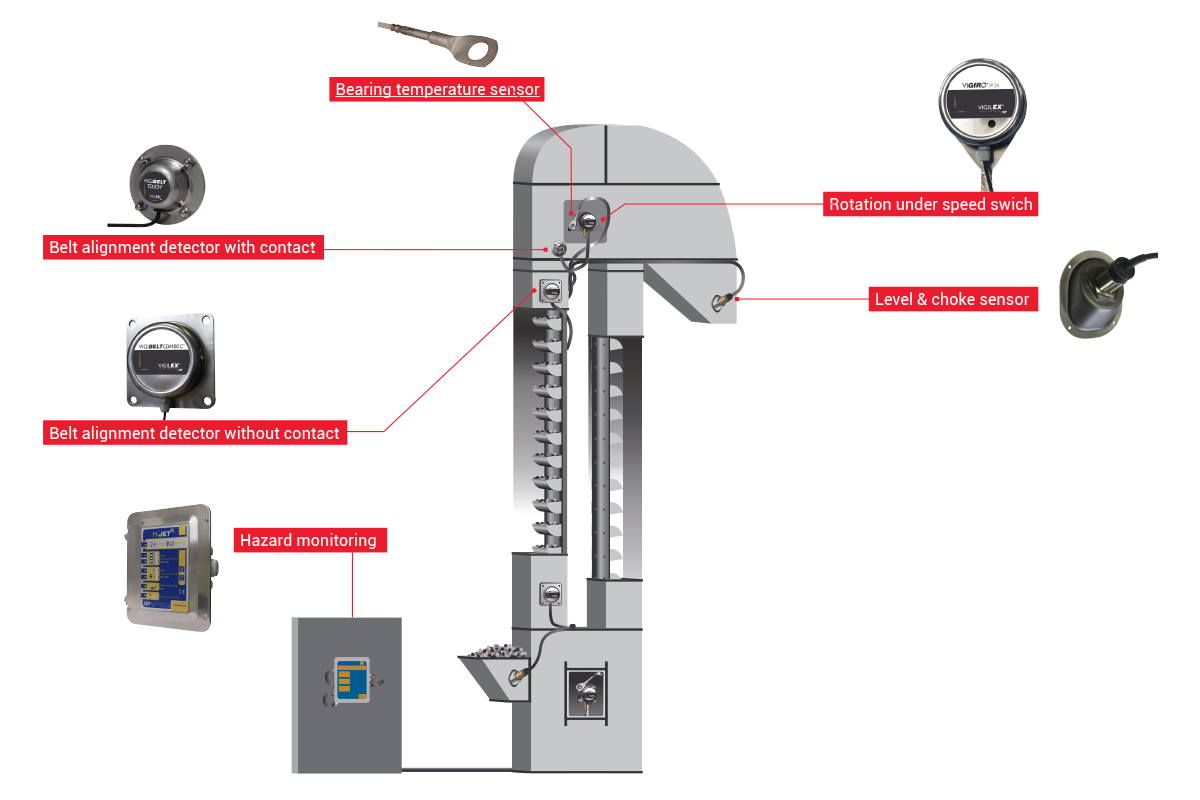

The M-JET system features a strong, dustproof, and waterproof casing, ensuring durability and protection in any environment. With remote management capabilities, you can easily monitor and control the system from a distance. It includes sensors for belt speed, choke and level, follower shaft position, bearing temperature, chain elongation, analogic, and belt alignment, providing comprehensive monitoring for optimal performance and reliability.

Contact us

THE HAZARD MONITORING DEVICES ARE ABLE TO MONITOR BUCKET ELEVATORS, BELT CONVEYORS, CHAIN CONVEYORS AND SCREW CONVEYORS.

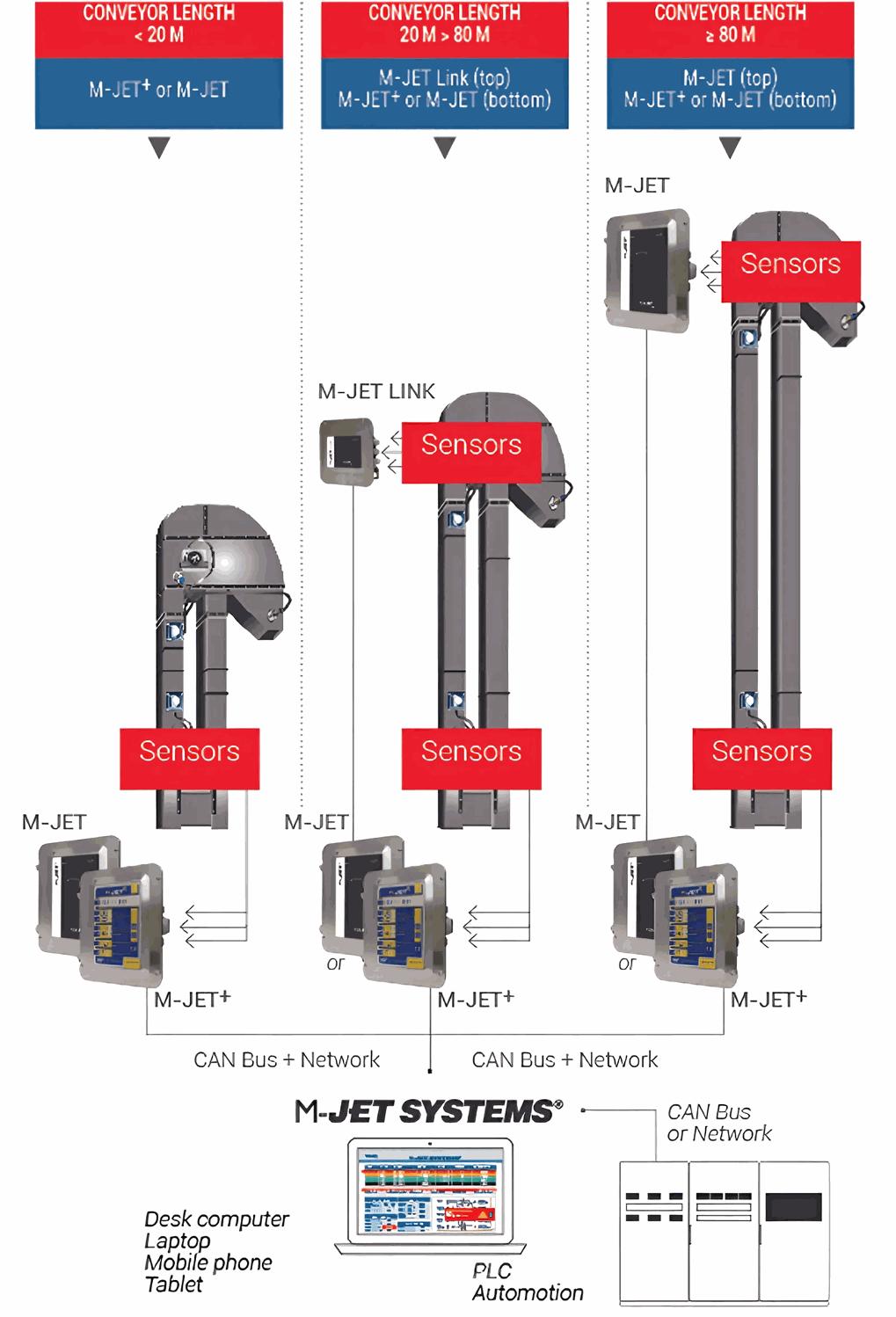

The M-JET hazard monitoring system operates by collecting data from an array of sensors strategically placed on conveyor equipment. Once wear points or hot spots are identified, the system promptly issues alerts, prompting timely maintenance interventions. This preemptive approach significantly mitigates the risk of expensive equipment failures and potential explosion hazards.

How the M-Jet Hazard Monitoring System works

By analyzing sensor data and storing information about detected defects, the system efficiently manages the conveyor's operational integrity. Depending on user settings, the M-JET+ or the M-JET will trigger alarms and initiate conveyor shutdown protocols as necessary.