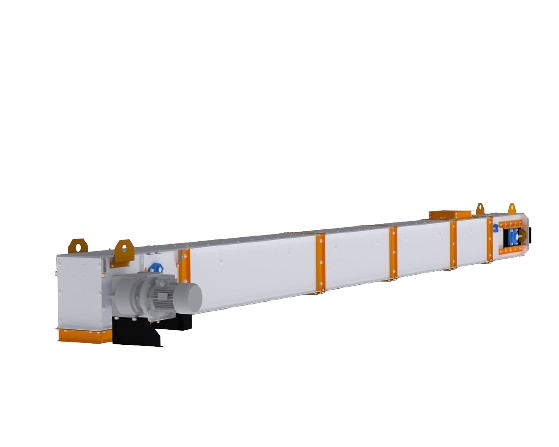

ECOFLOW ™

The raw material is loaded into the enclosed casing, and the product is then transported to the discharge area by the pulling conveyor section, which consists of a chain with cleats.

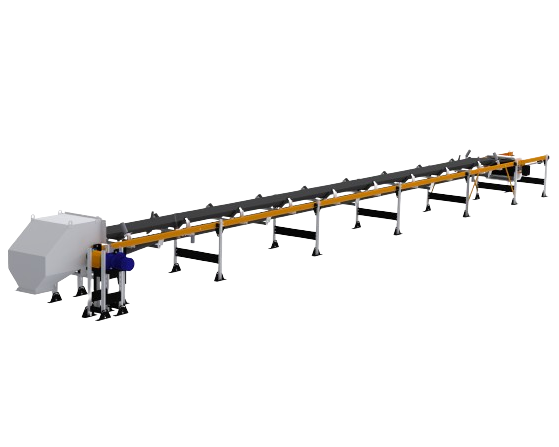

DURABELT ™

The bulk material is deposited into the charging hopper of the conveyor belt, and it is efficiently conveyed to the discharging area by the load-bearing elevator mechanism – the belt.

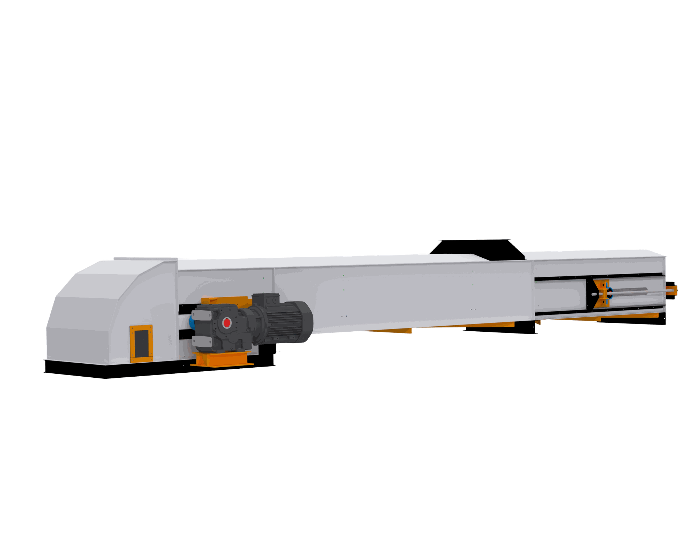

DURABELT SHUT ™

The sealed belt conveyor serves as a continuous transport system with a functional component in the shape of a belt. It facilitates the movement of bulk cargo in horizontal, inclined (-10° to +30°), and combined horizontal-inclined positions.

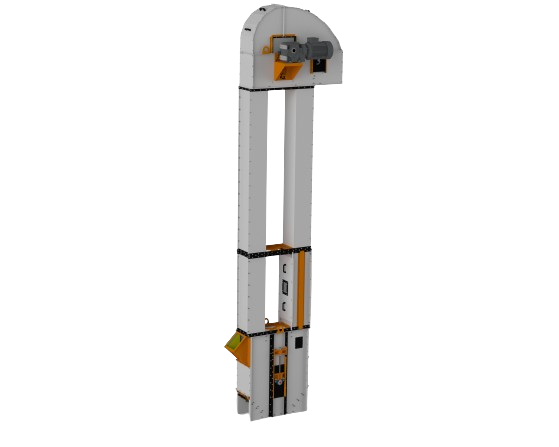

ECOTRU ™

The bulk material is introduced into the buckets, initiated by the elevator, scooped by the buckets, and subsequently elevated through the operational duct. At the head of the bucket elevator, the discharge of the buckets occurs centrifugally.