DRYING TECHNOLOGIES

Strahl dryers are made with superior materials and workmanship, using high-level robotic technology and automation to make the products solid, strong and perfect in all conditions. The structure is always assembled and tested in-house before delivery to ensure maximum reliability.

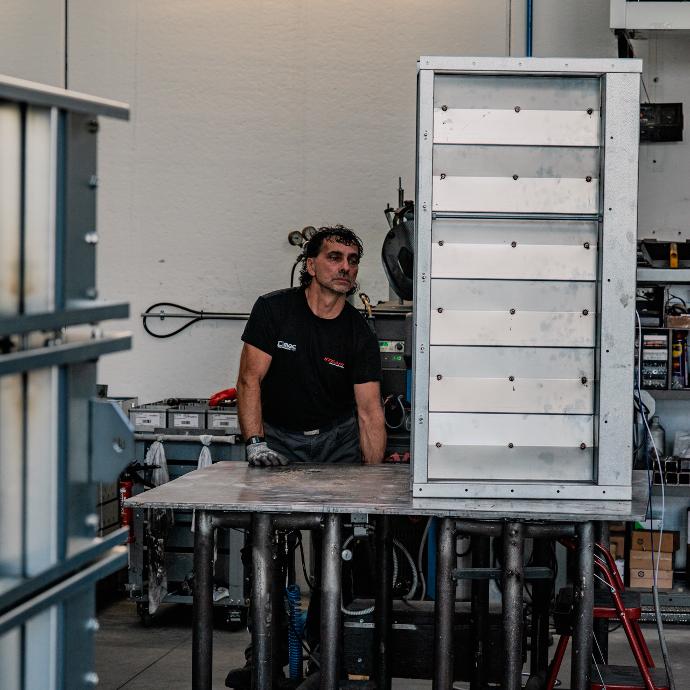

Dryers' structure

Strahl dryers emphasize meticulous design, featuring outer walls with drainage flaps to prevent corrosion. Smooth internal walls prevent product buildup, while Aluzinc outer cladding ensures durability and aesthetic appeal.

Protection against seismic events

In large dryers, special anchorage on a reinforced concrete base is provided to ensure resistance to the most extreme seismic events. The entire structure can be equipped with special tie-rods and fasteners to hold the dryer in place and protect internal equipment.

Dust reduction

The ventilation chamber is sized to have a low airflow speed, so dust decants and does not escape, and is designed to have the perfect balance of air and drying for the best results. The positioning of the fans also contributes to the reduction of dust dispersion.

Protection from rain

The outer panels are turned up to prevent water stagnation and thus prevent the machine from rusting over time. Inside, on the other hand, the panels are smooth so as not to retain the product.

Protection from wind

The structure is designed to be particularly resistant not only to external wind pressure but also to the negative internal pressure generated during emptying. This is also true for larger dryers.

Extraction device

The special conformation of this element allows very fast output of the product while keeping its shape and quality characteristics intact.

Efficiency at every stage of drying

To contain energy consumption, our dryers are equipped with devices to control and manage all operational phases, optimizing the resources used and minimizing energy dispersion.

Thanks to these solutions, Strahl dryers are able to concretely limit dispersion, waste and consumption, thus significantly increasing the efficiency and sustainability of processes.

Efficient drying

To curb energy consumption, dryers are equipped with devices to control and manage all operational stages, optimizing the resources used and minimizing energy loss.

Optimization and heat recovery

Many measures in stationary and mobile dryers allow maximum use of the heat produced. Many models, for example, are equipped with thermal insulation such as glass wool, which minimizes heat loss and reduces the need for additional heating. Some models in the stationary dryer series are also equipped with recirculation systems for air that is not fully saturated with moisture, which is thus recovered and reused, ensuring great fuel savings.

Controlled air flow

Each fan is designed and engineered for the dryer on which it is to be mounted. The blades are adjusted according to the specifications of the machine and the amount of air required for a perfect drying cycle. The full-to-vacuum ratio of each fan is always calculated on the most important principle: achieving the best operating range of the machine.

Burners

Air vein burners keep the flame even across the entire width. The special conformation allows perfect temperature control and the achievement of perfect drying at all times, without waste in fuel.

Control systems

To manage drying processes in real time and optimize results, our control systems allow the adjustment of temperature, humidity, and drying time based on the characteristics of each individual batch. This ensures that each lot is treated specifically, achieving perfect drying every time. Additionally, process data can be recorded to enable historical analysis and statistical monitoring.

Drying software

The dryers are equipped with state-of-the-art temperature and humidity control software that ensures perfect drying at all times, for any type of grain or oilseed.

Optimizing the process means reducing excessive consumption and waste.

Control panel

The operator panel is high-resolution, with an improved and simplified interface that allows very easy program management and high customization possibilities. The process management experience is pleasant, intuitive and comprehensive.

Software self-diagnostic system

The operation of the various components is constantly tested and monitored. The information gathered is processed by the software. The result is an advanced and intelligent diagnostic system that allows the operation of the dryer to be adapted to various conditions of use easily and safely.