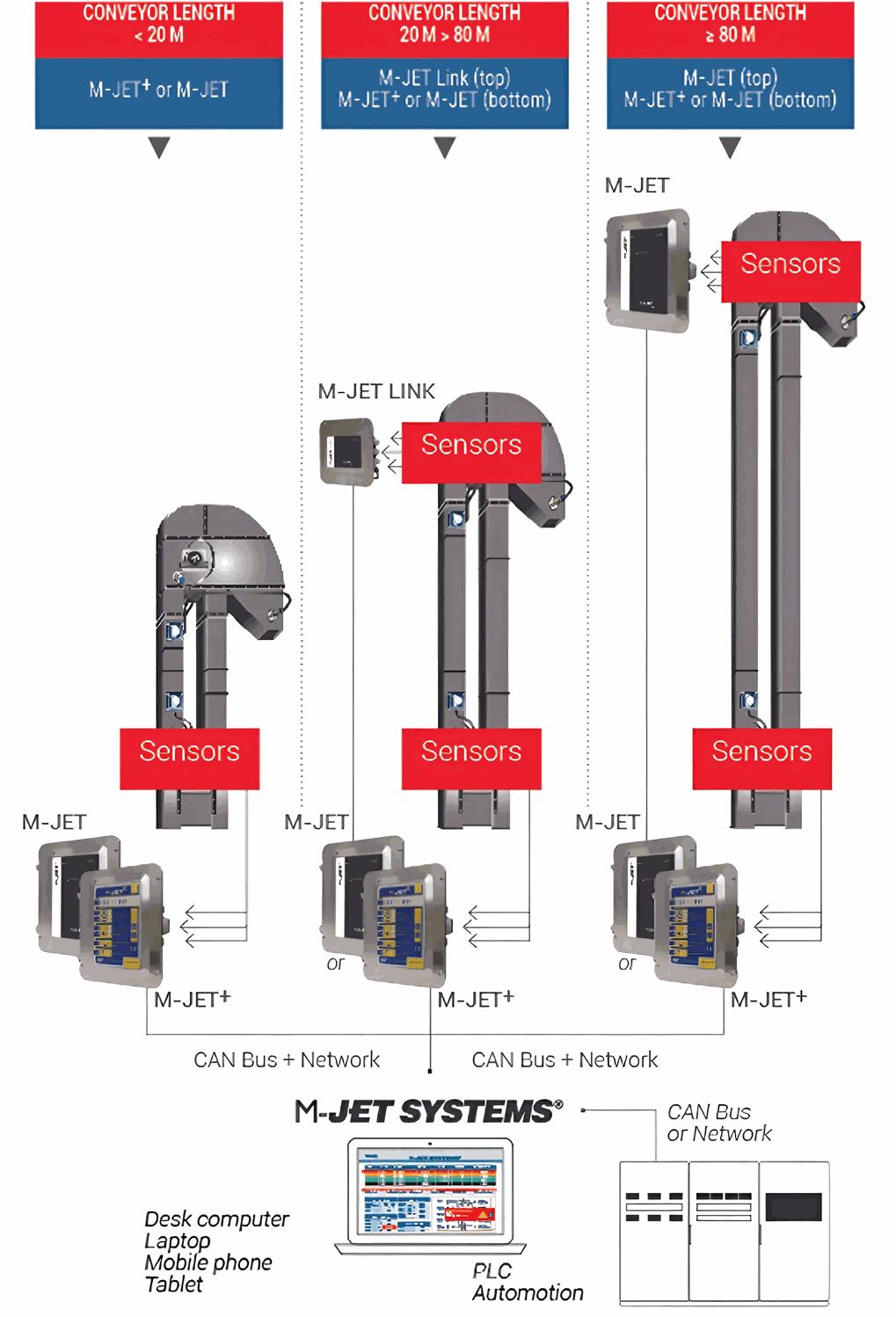

M-JET LINK

The BURST SENSOR serves as a highly effective indicator of the status of safety devices, providing real-time alerts to enhance the safety of your facilities.

It facilitates the connection of sensors to the Master M-JET+ or M-JET systems for individual conveyors via extension wires (multicables).

Additionally, a connection box is available for conveyor lengths ranging from 20 meters to 80 meters, ensuring seamless integration and extended coverage.

Contact us

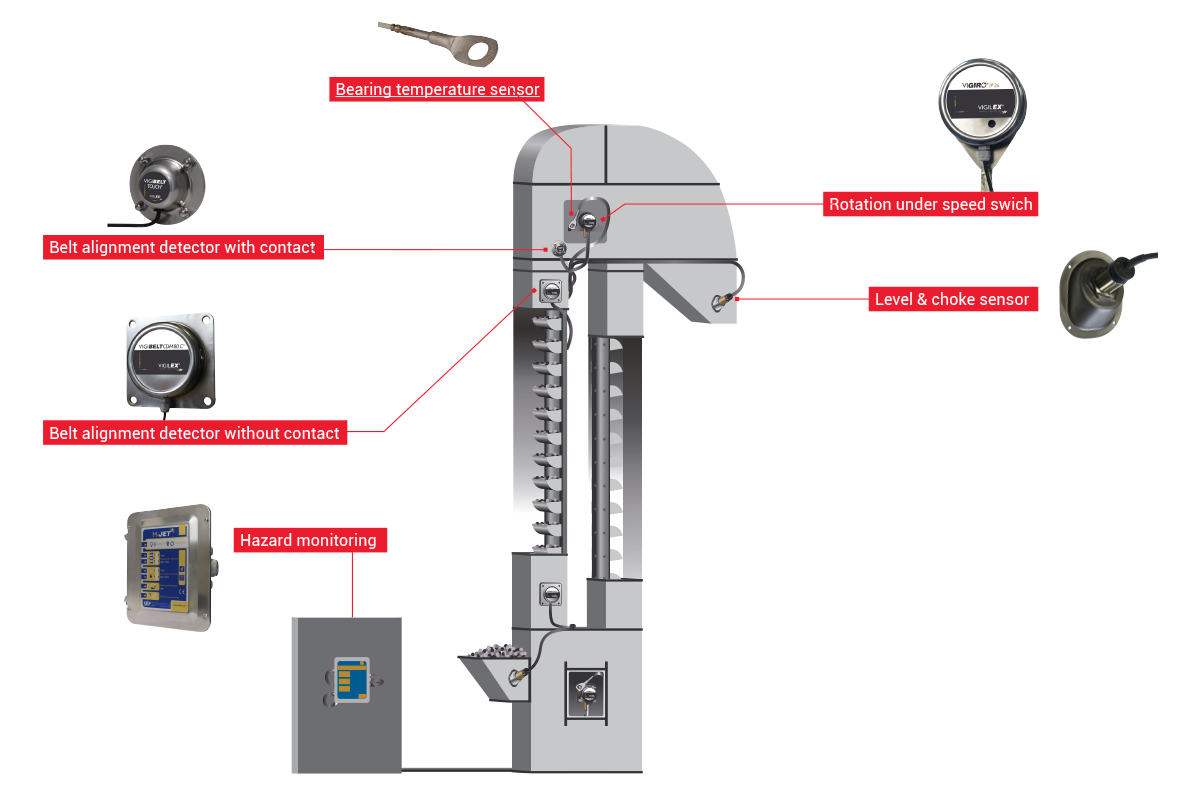

THE HAZARD MONITORING DEVICES ARE ABLE TO MONITOR BUCKET ELEVATORS, BELT CONVEYORS, CHAIN CONVEYORS AND SCREW CONVEYORS.

The M-JET hazard monitoring system operates by collecting data from an array of sensors strategically placed on conveyor equipment. Once wear points or hot spots are identified, the system promptly issues alerts, prompting timely maintenance interventions. This preemptive approach significantly mitigates the risk of expensive equipment failures and potential explosion hazards.

How the M-Jet Hazard Monitoring System works

By analyzing sensor data and storing information about detected defects, the system efficiently manages the conveyor's operational integrity. Depending on user settings, the M-JET+ or the M-JET will trigger alarms and initiate conveyor shutdown protocols as necessary.