HOPPER SILOS

Hopper silos are generally used when complete emptying of the silo is necessary and frequent, for example to ensure plant traceability to avoid cross-contamination in the process and are characterised by its easy unloading.

SiloMasters hopper silos are available with capacities from 15 m³ up to 3.500 m3, in its version with 45⁰ hopper and in capacities from 15 m³ up to 2.500 m3, in the version with 60⁰ hopper.

Contact us

Characteristics of Hopper silos:

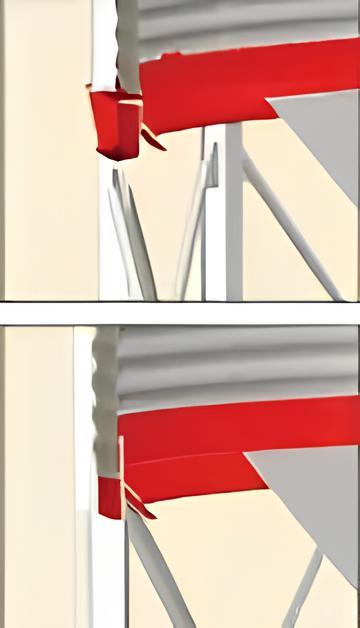

To support the high loads in the transition from the cylinder to the hopper, a compression ring is utilised in the joint of the silo cylinder and the hopper. We supply this ring in two variants, the heavy version and the light version for smaller silos. These rings guarantee a great resistance of our hopper silos. Our hopper sheets are made of high resistance steel S450GD, with a high strength and elasticity. Support structure is composed of cold-formed profiles for the ‘Neper’ series silos and hot-rolled profiles for the ‘Inti’ series silos.

To support the high loads in the transition from the cylinder to the hopper, a compression ring is utilised in the joint of the silo cylinder and the hopper. We supply this ring in two variants, the heavy version and the light version for smaller silos. These rings guarantee a great resistance of our hopper silos. Our hopper sheets are made of high resistance steel S450GD, with a high strength and elasticity. Support structure is composed of cold-formed profiles for the ‘Neper’ series silos and hot-rolled profiles for the ‘Inti’ series silos.