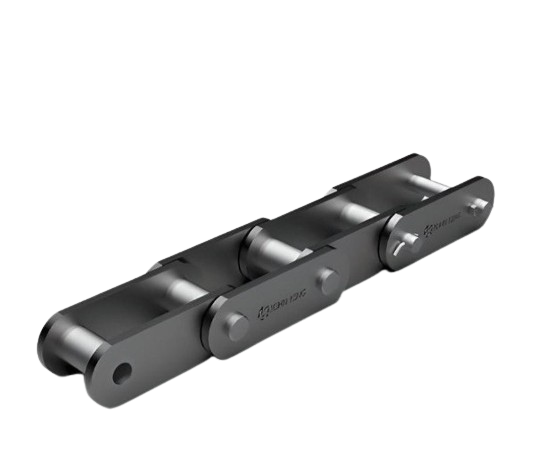

KALAPÁCSOLT LÁNCOK

A kalapácsolt villa láncok megbízhatóságukkal, sokoldalúságukkal, szilárdságukkal és kopásállóságukkal tűnnek ki. A dupla szálas összeállítások szabványos formátumot kínálnak, kalapácsolt „dupla bilincs”-sel a kaparó rögzítésére, míg az extra széles szállítószalagokhoz elérhető a háromszoros lánc, amely lehetővé teszi három láncszál kombinálását, összesen akár 3100 mm-es peremekig a dupla láncokkal.

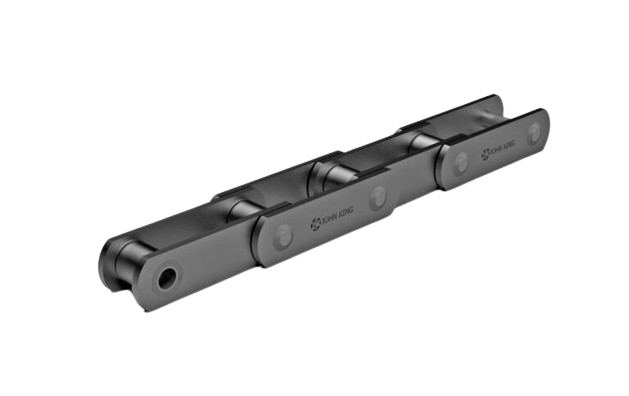

WELDED STEEL CHAINS

Az eltolásos oldallemezzel és körben hegesztett persellyel rendelkező láncok maximális szilárdságot és kiváló kopásállóságot biztosítanak, köszönhetően a hagyományos edzési keményítésnek és a perselyek, illetve csapok felületi indukciós edzésének, így tökéletesek nagy igénybevételű alkalmazásokhoz.

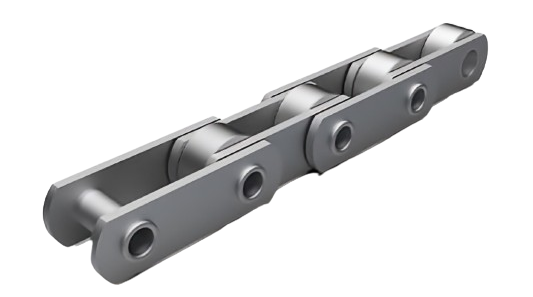

AMERIKAI SZTÁNDARDBELI MŰSZAKI LÁNCOK

A láncos szállítószalagok, amelyek ideális választást jelentenek az időszakos anyagkezeléshez, tökéletesen illeszkednek az amerikai sztandard műszaki láncokhoz, melyek görgős és nem görgős változatokban érhetők el, sokoldalú rögzítésekkel. A perselyes láncok, más néven acélujjláncok, a görgős szállítószalagok szerkezetét követik, a görgő kivételével.

METRIKUS LÁNC M/FV

Az M sorozat terhelhetősége 20 kN-tól 900 kN-ig terjed, és 40 mm-es vagy 600 mm-es lépésközzel rendelkezik. Az FV sorozat, amely az M sorozattal összehasonlítható, sőt, néha azzal megegyező; valamint az egyedülálló WHM sorozat, amely hegesztett acélláncokból készült, és a M sorozat perselyes láncaival megegyező méretekkel rendelkezik a DIN 8167 szabvány szerint.

BRITISH STANDARD SZÁLLÍTÓ LÁNCOK

A brit szabvány hengeralakú láncokat ír elő a szállítószalagokhoz, melyek rögzített szerkezettel rendelkeznek. A szabvány előírja, hogy a szabványos anyagválasztásban kis ötvözetű acélt kell alkalmazni, felületi keményítéssel.

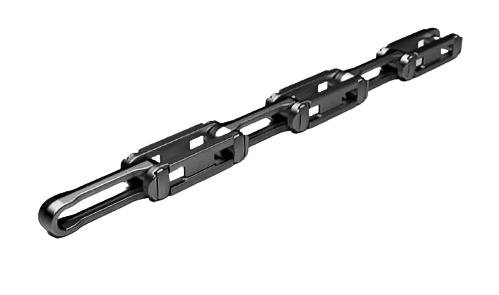

RÖGZÍTÉS NÉLKÜLI LÁNC

A rögzítés nélküli lánc erős és egyszerű szerkezettel rendelkezik, kedvező erő- és súlyarányt biztosítva, így ideálisan alkalmazható felülről hajtott kocsikhoz, kaparószárnyakhoz és összeszerelő szállítószalagokhoz. Mind a szabványos, mind az X típusú láncok elérhetők ötvözetacélból. Az X sorozat kétirányú hajlítást biztosít, így ideális felülről hajtott rendszerekhez, amelyek függőleges íveket tartalmaznak. Számos rögzítési lehetőség áll rendelkezésre, lehetővé téve széleskörű alkalmazási lehetőségeket.