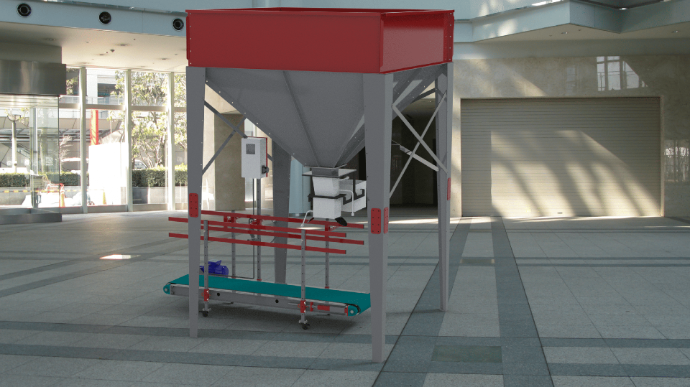

GABONÁTÁROLÁS MÓDSZEREI

Tudjon meg többet

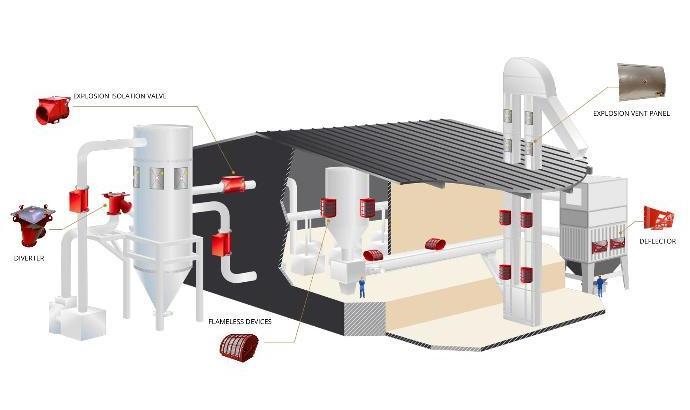

ASPIRÁCIÓS TECHNOLÓGIÁK

Tudjon meg többet

SZÁRÍTÓ TECHNOLÓGIÁK

Tudjon meg többet